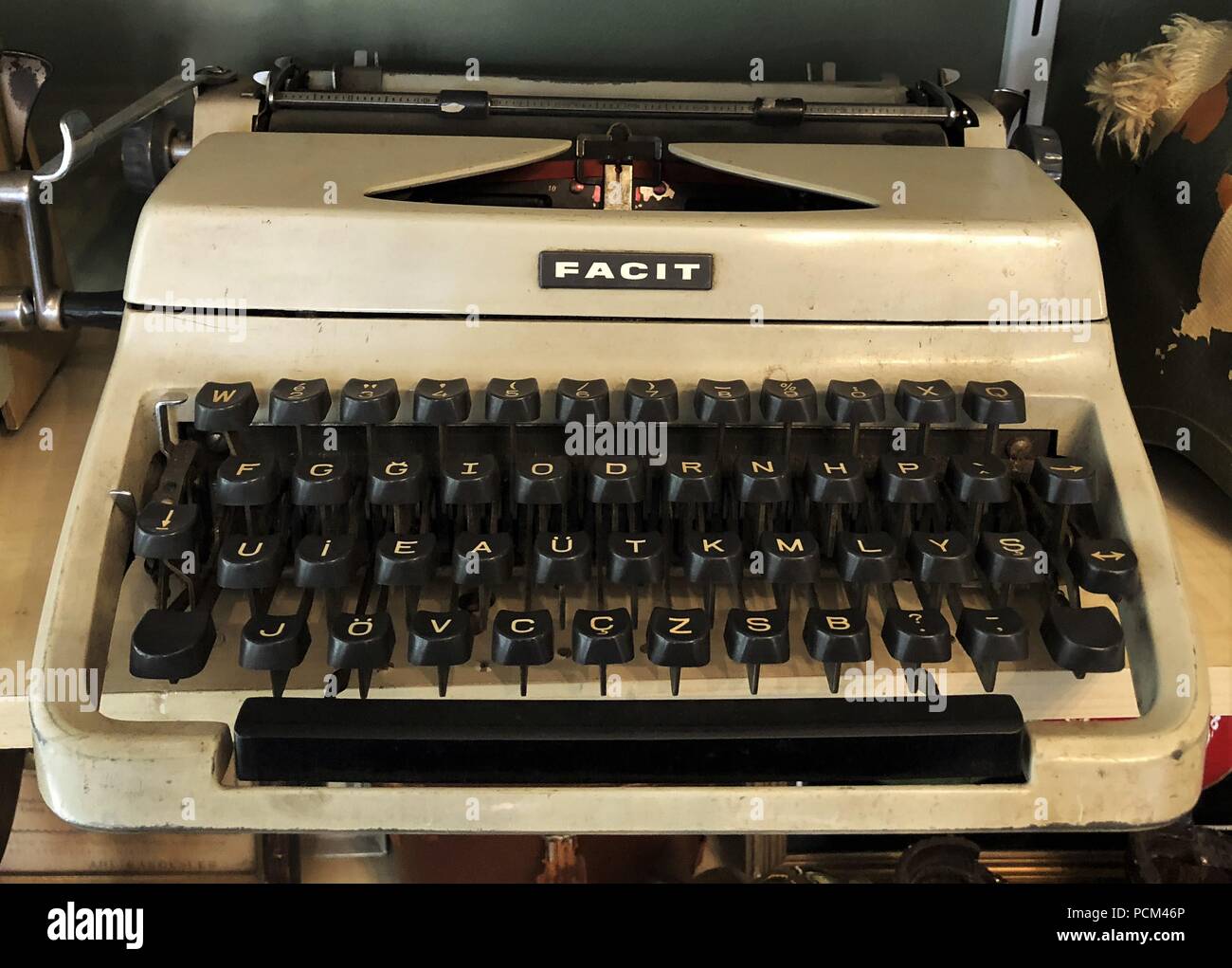

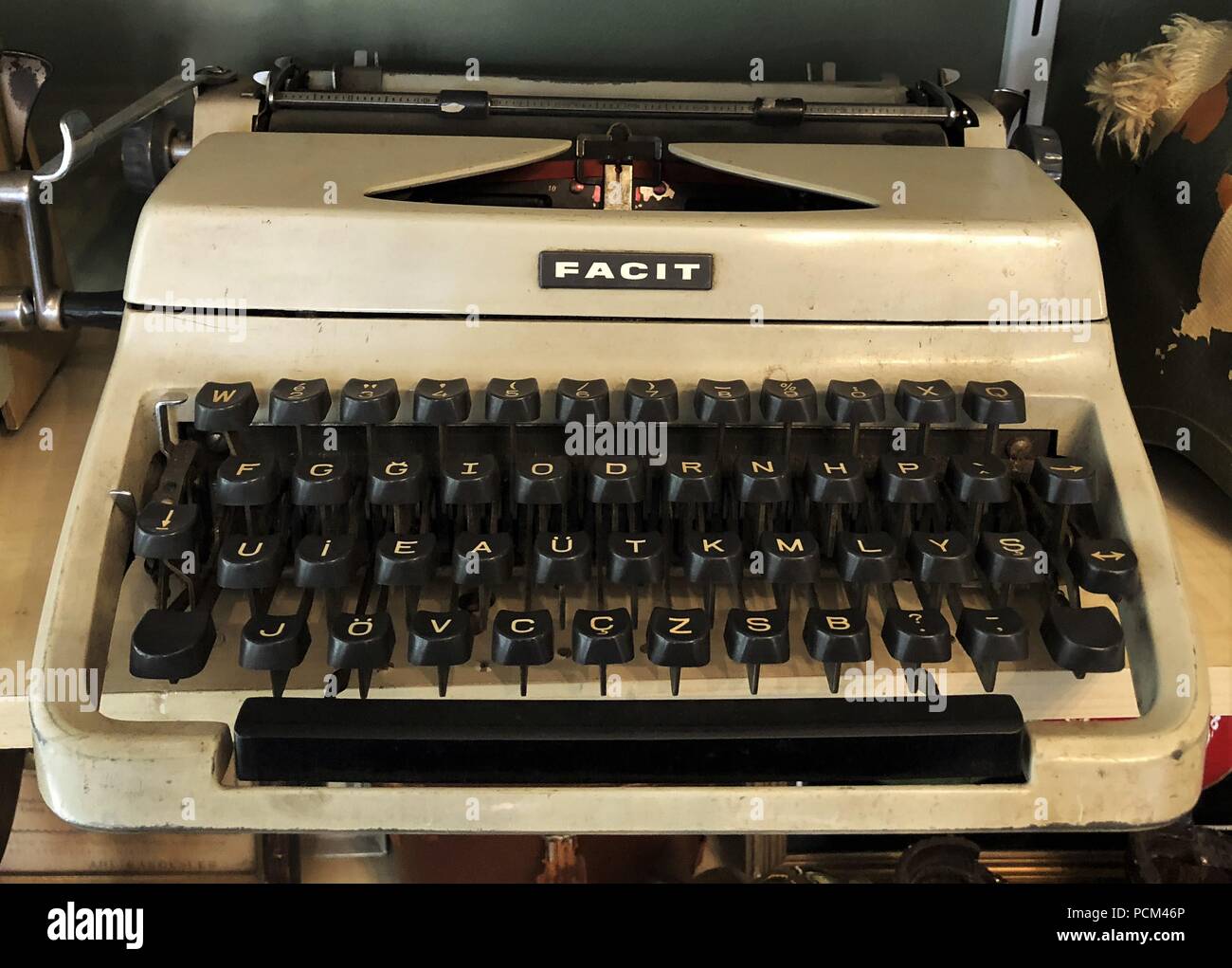

FACIT TYPEWRITER MANUAL FREE

This indicates that the escapement bearing is not yet free enough and the force you are using is too high.

If you feel resistance and hear a grinding sound, it is the spring-loaded rack being forced off the escapement pinion. As it becomes adequately free, you will then be able to move the carriage from left to right while watching the escapement wheel moving. Once the escapement has freed a little, you can move the escapement pawl out of the way with a thumb while you gently experiment with increasing the range of escapement wheel movement. Re-apply and wait another day if necessary. In my experience, the escapement bearing may free completely and suddenly, or it may remain quite resistant for a while. If it is still unyielding, re-apply your penetrating solvent and wait another day. The following day, you can use (GENTLY!) a pair of needle-nosed pliers to test the performance of the solvent, by GENTLY (you’ll be sad if you break an escapement tooth), attempting to rock the escapement wheel back and forth. X over it: Mystery Solved! The Frozen Facit (Starring Facit 1620) The aim is to dissolve the old “lubricant”, and here is a very useful post about another solvent product that has been used successfully: I apply this at the top and bottom of the escapement bearing, using a long, fine, blunt syringe needle to reach underneath the escapement wheel and also underneath the pinion (the gear-wheel that engages with the carriage rack) on top. Of course, definitions of “available” and “reasonable” will vary, but here is what I have used with apparent success:Īs a penetrating lubricant I use CRC 5-56.

What is reasonably safe for the typewriter. What is reasonably safe for humans to handle. So, what solvent/lubricant to use? There is quite some discussion about this, so I looked at three criteria: It allows precise location and dose, and minimises the risk of solvent/lubricant causing problems elsewhere. I use a syringe with a blunt needle for this purpose. To free the seized bearing, a solvent and/or lubricant must be introduced. Here is a closer picture of the escapement – the victim of the slow-acting cement used by Facit in the escapement bearing:īelow is a view from the “top” (seen here with the carriage resting on its back) with the carriage moved all the way to the left: Gently place the carriage on your work mat as shown, and set aside the rest of the typewriter for now: Some people may prefer to then remove the entire escapement unit for very thorough cleaning, but in my experience (with more than a dozen seized Facit typewriters) it is rarely necessary and brings risks of its own. It seems that the carriage was designed to be very easily removable. NOTE: There is no need to be concerned at this stage about any other springs, linkages, the mainspring, draw-string etc. Remove the two outer screws and then carefully lift the carriage away. Again using the the carriage-release lever, (because the escapement is seized) move the carriage all the way to the right to expose the screws that hold the carriage on the left side. I would recommend that the adjusting cam and screw remain untouched at this time. You will see that the carriage is held in place on the right by two screws, with an adjusting cam and screw in between them. Set the left and right margins to their extremes, and use the carriage-release lever to the move the carriage all the way to the left. Re-position the typewriter so that it is facing you as if for typing. Remove the spring shown with a spring hook and some needle-nose pliers. Place the typewriter on its back on a soft work surface (I use a piece of “BORRIS” or “KRISTRUP” door mat from Ikea) and you will see that there is an access hole on the base of the typewriter. Here’s how I like to fix the seized bearing problem:

0 kommentar(er)

0 kommentar(er)